Urethane bumper parts are crucial for modern vehicle safety and repair. They offer a lightweight yet durable alternative to traditional metal bumpers, simplifying replacement processes and saving on labor costs. However, complex designs and limited genuine parts availability pose challenges in traditional repair methods. Advances in manufacturing technologies like 3D printing and digital design software have significantly reduced turnaround times, minimizing design and production efforts for custom urethane bumper parts. These innovations streamline car body repairs, enabling efficient vehicle collision resolutions and quick vehicle reactivation.

In today’s fast-paced world, quick turnaround times for vehicle repairs are crucial. One component often overlooked but vital to safety is the urethane bumper—its damage can significantly impact a car’s overall performance and aesthetics. Traditional bumper repair processes often involve lengthy wait times due to labor-intensive methods. However, advancements in manufacturing have introduced rapid solutions for urethane bumper parts replacement, ensuring fast turnaround times without compromising quality. This article explores these innovations, highlighting the benefits of swift repairs for both consumers and automotive businesses.

- Understanding Urethane Bumper Parts and Their Importance

- Challenges in Traditional Bumper Repair and Turnaround Times

- Innovations in Fast Turnaround for Urethane Bumper Parts Replacement

Understanding Urethane Bumper Parts and Their Importance

Urethane bumper parts are integral components that play a significant role in modern vehicle design and safety. These parts, made from durable and flexible urethane, serve as crucial protectors during impact, absorbing energy and minimizing damage in collisions. Their importance is manifold; they not only enhance the aesthetic appeal of a vehicle by providing a sleek, seamless finish but also contribute to overall structural integrity. A well-maintained bumper system, including these specialized parts, can significantly reduce the costs associated with fender repair or even more extensive car collision repair.

In the realm of vehicle paint repair and fender repair, urethane bumper parts offer a game-changer solution. Unlike traditional metal bumpers, which can be heavy and rigid, urethane alternatives provide a lightweight yet robust option that can be easily replaced in case of damage. This swift replacement process not only ensures faster road return for vehicles but also saves on labor costs related to extensive vehicle body repairs. Moreover, the ease of installation allows for efficient fender repair, making it an attractive choice for both automotive professionals and DIY enthusiasts looking for quick, effective solutions.

Challenges in Traditional Bumper Repair and Turnaround Times

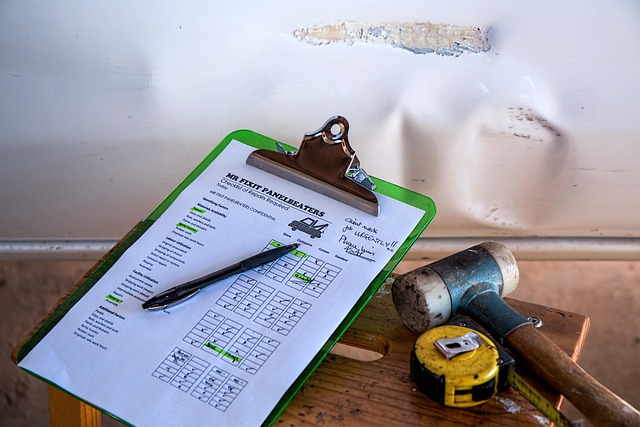

In traditional bumper repair processes, several challenges arise that can significantly impact turnaround times. One of the primary hurdles is the complexity and intricate nature of modern vehicle bumpers, which often incorporate various materials like metal, plastic, and urethane components. This complexity necessitates specialized skills and equipment for effective disassembly, inspection, and subsequent reassembly, leading to extended repair durations.

Moreover, the availability of genuine replacement parts can be a bottleneck in expediting the repair process. For rare or out-of-production urethane bumper parts, auto repair shops might face delays in sourcing them from manufacturers or distributors, causing further postponements in the overall turnaround time. These challenges highlight the need for efficient alternative solutions, such as rapid manufacturing techniques and accessible aftermarket parts, to meet the growing demand for swift bumper repairs, especially in today’s fast-paced automotive industry.

Innovations in Fast Turnaround for Urethane Bumper Parts Replacement

In today’s fast-paced world, where convenience and speed are paramount, the automotive industry is constantly evolving to meet these demands. Innovations in manufacturing and part replacement have led to significant improvements in turnaround times for urethane bumper parts, specifically. Advanced technologies like 3D printing and digital design software enable auto collision centers to streamline the process, reducing the time traditionally spent on designing and producing custom urethane bumper parts.

These cutting-edge approaches facilitate faster car body repair without compromising quality or precision. As a result, vehicle collision repairs can be completed more efficiently, ensuring that vehicles are back on the road promptly. With these advancements, what was once a time-consuming task is now a game-changer in the field of auto collision centers, revolutionizing how we approach urethane bumper parts replacement and enhancing overall customer satisfaction.

In light of the above, it’s clear that fast turnaround times for urethane bumper parts replacement are not only desirable but essential in today’s automotive industry. By embracing innovations like advanced manufacturing techniques and digitalization, repair shops can significantly reduce turnaround times without compromising quality. This, in turn, enhances customer satisfaction, ensures faster roadworthiness, and contributes to the overall efficiency of collision repair processes.