Advanced formulation techniques and 3D printing are revolutionizing urethane bumper parts manufacturing. These innovations offer superior impact resistance, durability, flexibility, and aesthetics, catering to both classic and modern vehicles. New production methods combine innovative raw materials with precise molding for enhanced dent repair and weather resistance, ensuring urethane bumper parts can withstand daily driving conditions, extending lifespans and enhancing vehicle safety.

“Revolutionize your vehicle’s protection with the latest innovations in urethane bumper parts manufacturing. This cutting-edge guide explores advanced formulation techniques, highlighting how modern urethanes are enhancing impact resistance and durability. We delve into the transformative role of 3D printing, offering precise and customizable bumper designs. Furthermore, discover new production methods that promise superior performance and aesthetic appeal. Stay ahead of the curve with these game-changing advancements in urethane bumper parts.”

- Exploring Advanced Urethane Formulation Techniques

- The Rise of 3D Printing in Bumper Part Manufacturing

- Enhancing Durability: New Production Methods for Urethane Bumpers

Exploring Advanced Urethane Formulation Techniques

In the realm of urethane bumper parts manufacturing, the exploration of advanced formulation techniques is revolutionizing the industry. By delving into innovative chemical compounds and specialized polymers, manufacturers are crafting urethane materials that not only match but often exceed the performance of traditional components. This involves meticulous mixing and curing processes to achieve optimal durometers and flexibility, ensuring superior impact resistance and durability in both classic car restoration and luxury vehicle repair applications.

These cutting-edge techniques allow for precise tailoring of urethane properties, catering specifically to diverse automotive needs. For instance, softer urethanes can provide enhanced shock absorption, ideal for vintage vehicles with original hardware, while harder formulations excel in high-stress areas, contributing to the overall strength and longevity of modern automotive repair services. Such advancements not only streamline production but also offer superior aesthetics, ensuring that urethane bumper parts seamlessly integrate into both classic and contemporary vehicle designs.

The Rise of 3D Printing in Bumper Part Manufacturing

The automotive industry is experiencing a significant shift as 3D printing technology transforms urethane bumper parts manufacturing. This innovative process offers unparalleled precision and customization, enabling the creation of complex geometric designs that were previously impossible to achieve with traditional methods. By reducing production time and minimizing material waste, 3D printing has become a game-changer for tire services and luxury vehicle repair workshops.

With its ability to produce lightweight, durable, and highly specialized urethane bumper parts, this technology is not just revolutionizing vehicle body repair but also opening up new possibilities for design and functionality. Manufacturers can now create unique, personalized components tailored to specific customer needs, enhancing the overall aesthetic appeal of vehicles while ensuring optimal safety and performance.

Enhancing Durability: New Production Methods for Urethane Bumpers

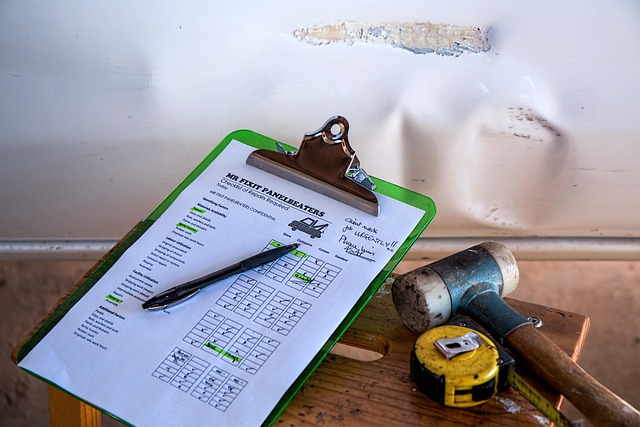

In recent years, advancements in manufacturing techniques have significantly enhanced the durability of urethane bumper parts. New production methods employ innovative combinations of raw materials and precise molding processes to create components that are not only stronger but also more resilient to the rigors of daily driving and potential collision damage repair. These upgrades are particularly beneficial for vehicle dent repair, as urethane’s flexibility allows it to absorb impact energy without compromising structural integrity, thus reducing the need for extensive car bodywork services.

The enhanced durability is a result of meticulous research aimed at developing formulations that offer superior resistance to weathering, UV exposure, and chemical corrosion. By integrating these improvements into the manufacturing process, producers ensure that urethane bumper parts can withstand the challenges of modern driving conditions. This not only extends the lifespan of these components but also contributes to overall vehicle safety by maintaining optimal collision response capabilities.

Innovations in urethane bumper parts manufacturing are revolutionizing the automotive industry. Advanced formulation techniques, such as those explored in this article, and emerging technologies like 3D printing are driving up durability, quality, and efficiency. As new production methods continue to evolve, we can expect even more robust and reliable urethane bumper parts, ensuring safer and smoother journeys on the road ahead.