Rigorous testing protocols ensure urethane bumper parts meet safety standards and withstand real-world impacts, including frontal and rear collisions. These tests evaluate durability, impact resistance, structural integrity, environmental impact, and long-term reliability, prioritizing driver and passenger safety. Quality assurance measures include tensile strength assessments and high-speed impact simulations, ensuring compliance with regulatory body standards for reliable protection during severe collisions.

Urethane bumper parts are integral to vehicle safety, absorbing impact energy during collisions. This article explores the rigorous testing protocols that ensure these components meet stringent safety standards. From understanding simulation techniques to delving into quality assurance checks, we uncover how manufacturers validate the performance of urethane bumper parts. By simulating real-world impact scenarios and adhering to industry standards, these tests guarantee the reliability and safety of urethane bumper parts, enhancing passenger protection on the road.

- Understanding Urethane Bumper Parts Testing Protocols

- Simulating Real-World Impact Scenarios

- Ensuring Compliance: Quality Assurance Checks and Standards

Understanding Urethane Bumper Parts Testing Protocols

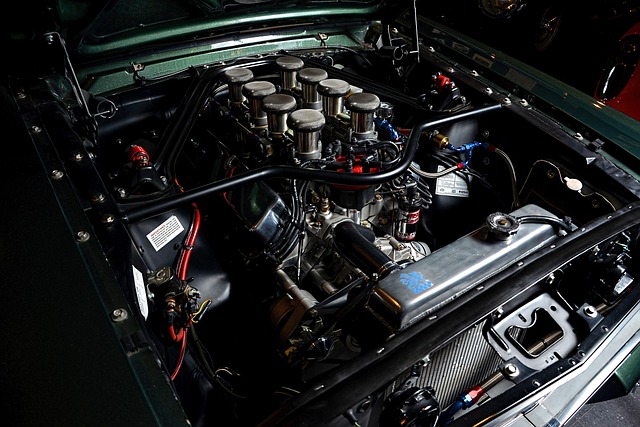

Urethane bumper parts testing protocols are designed to ensure these components meet stringent safety standards. This rigorous process involves a series of simulations and evaluations aimed at replicating real-world scenarios, such as minor collisions or fender benders. The tests assess the durability, impact resistance, and overall structural integrity of the urethane parts. Engineers subject these materials to extreme forces and pressures, mimicking various collision repair scenarios, to gauge their performance under stress.

The testing protocols not only consider the physical attributes but also the environmental impact and long-term reliability. This comprehensive approach ensures that urethane bumper parts can withstand everyday wear and tear without compromising safety during car body repair processes. By adhering to these strict guidelines, manufacturers guarantee that drivers and passengers remain protected in the event of a collision, making urethane bumper parts a preferred choice for collision repair professionals.

Simulating Real-World Impact Scenarios

To ensure the safety and effectiveness of urethane bumper parts, various testing methods are employed to simulate real-world impact scenarios. These tests go beyond basic laboratory conditions by recreating the forces and circumstances that vehicles might encounter on the road. For instance, engineers use specialized equipment to mimic frontal and rear collisions, replicating the speed, angle, and energy transfer of typical accidents. This simulation involves subjecting urethane bumper parts to rigorous impacts and deformations, checking their resilience and ability to absorb shock without compromising structural integrity.

Moreover, these tests often incorporate assessments of the part’s compatibility with vehicle paint repair and bodywork processes. As urethane is commonly used in modern autobody repairs for its durability and aesthetic appeal, ensuring that bumper parts can withstand the application of paint and integration into the existing vehicle bodywork is crucial. This includes evaluating how well the urethane maintains its shape and structural properties after being crumpled or impacted, while also considering any potential effects on the surrounding vehicle paint repair process.

Ensuring Compliance: Quality Assurance Checks and Standards

Urethane bumper parts undergo rigorous quality assurance checks to ensure they meet industry standards and regulations, thereby guaranteeing safety and performance. These tests are designed to verify the material’s strength, durability, and impact resistance—crucial attributes for any automotive component. Advanced testing methods, such as tensile strength assessments and high-speed impact simulations, replicate real-world conditions to predict how these parts will behave under various stresses.

Compliance with standards set by regulatory bodies is paramount. These standards dictate specific performance metrics, ensuring that urethane bumper parts not only prevent damage from minor bumps and scratches (like those often seen in car scratch repair or dent removal scenarios) but also maintain structural integrity during more severe collisions. Regular quality control measures help automobile manufacturers and aftermarket suppliers provide consumers with reliable, safe, and high-quality urethane bumper parts.

Urethane bumper parts undergo rigorous testing protocols to ensure they meet safety standards, mimicking real-world impact scenarios. Through simulated tests, these components are evaluated for their ability to withstand force and protect vehicles and occupants. Quality assurance checks and adherence to relevant standards guarantee that urethane bumper parts deliver reliable performance and safety in the event of a collision.