Urethane bumper parts offer superior durability and impact resistance compared to plastic and metal alternatives, making them a preferred choice in automotive sector for collision repair and maintaining vehicle aesthetics. Their unique properties include enhanced front-end protection, excellent weather & UV resistance, and high impact absorption capacity, ensuring structural integrity and lower maintenance costs.

Urethane bumper parts have emerged as a superior alternative to traditional plastic and metal components, offering unique properties that enhance vehicle performance and durability. This article delves into the world of urethane, exploring its advantages over competitors like plastic and metal in terms of impact resistance, flexibility, and longevity. We’ll guide you through the process of selecting the optimal material for your needs, considering various applications and essential factors.

- Understanding Urethane Bumper Parts: Properties and Benefits

- Plastic vs. Metal Alternatives: Durability and Performance Comparison

- Choosing the Right Material: Applications and Considerations

Understanding Urethane Bumper Parts: Properties and Benefits

Urethane bumper parts are known for their exceptional durability and flexibility, making them a top choice in the automotive industry. This innovative material offers unique properties that set it apart from traditional plastic and metal alternatives. One of its key advantages is the ability to withstand impact and absorb energy effectively during collisions or minor bumps, which translates into superior protection for your vehicle’s front end.

Additionally, urethane provides excellent resistance to weather conditions, UV rays, and chemicals, ensuring long-lasting performance without fading, cracking, or breaking. This makes it ideal for car dent repair and maintaining the overall aesthetics of a vehicle. Unlike plastic, which may shatter or become brittle over time, and metal, which can bend or rust, urethane bumper parts offer a reliable solution for autobody repairs, providing both strength and resilience in various environments.

Plastic vs. Metal Alternatives: Durability and Performance Comparison

When it comes to comparing urethane bumper parts with their plastic and metal alternatives, durability and performance are key considerations for any car owner or collision repair shop. Urethane, a highly versatile synthetic material, offers superior resilience compared to traditional plastics. It’s known for its exceptional impact resistance, making urethane bumper parts ideal for withstanding the forces involved in collisions, without compromising on structural integrity. This property not only ensures better protection for vehicles but also reduces the need for frequent replacements.

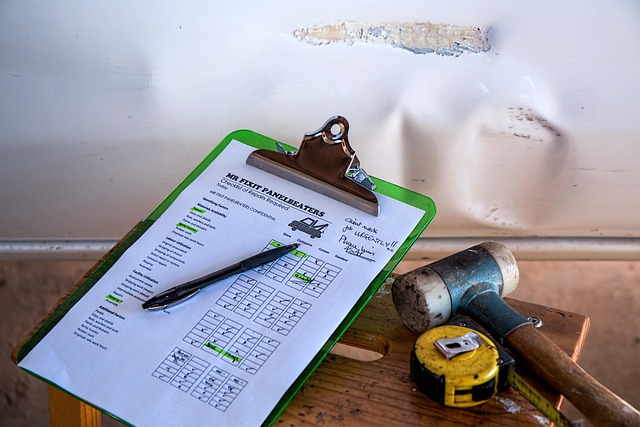

On the other hand, while metal bumpers have long been the standard, they can be more susceptible to corrosion and denting over time, especially when exposed to harsh weather conditions or road debris. Plastic alternatives, while lighter and often easier to install, may not match urethane’s durability in terms of withstanding intense impacts. In a collision repair center, choosing the right material is crucial for both aesthetic restoration and long-term functionality. By prioritizing quality urethane bumper parts, car owners can expect enhanced performance, increased longevity, and potentially lower maintenance costs over time, making it a practical choice for scratch repair or more severe damage scenarios.

Choosing the Right Material: Applications and Considerations

Choosing the right material for bumper parts is a crucial decision that depends on various factors and specific applications. Urethane bumper parts offer a unique set of advantages, especially in terms of durability and impact resistance. This flexible polymer can withstand severe impacts and maintain its shape, making it ideal for auto body services where protection against minor collisions and scratches is essential.

When comparing urethane to plastic or metal alternatives, consider the environment and intended use. Plastic may be lighter but lacks urethane’s ability to absorb impact energy, making it more susceptible to cracking in high-stress areas. Metal, while strong, can be more prone to corrosion and weight issues, impacting tire services and overall vehicle performance. Urethane provides a balance of strength, flexibility, and resistance to degradation, making it a preferred choice for many automotive body shops seeking reliable and long-lasting bumper solutions.

Urethane bumper parts offer a compelling blend of durability, flexibility, and impact resistance, making them an excellent choice for various applications. While plastic and metal alternatives have their merits, urethane’s unique properties position it as a superior option in many cases. When considering the right material for your needs, understanding the specific advantages of urethane bumper parts can help ensure optimal performance and longevity.